Introduction to Multiple Effect Evaporators

A Multiple Effect Evaporator (MEE) is a sophisticated device designed to remove water from liquids using steam. Unlike single-effect evaporators, which discard the steam after one use, MEEs reuse steam across multiple stages, making them significantly more energy-efficient. This technology is crucial in various industries, such as food processing, pharmaceuticals, chemicals, and wastewater treatment, where large volumes of liquid need to be concentrated or purified. Goldfinch Evaporator Systems specializes in providing tailored feed-in Multiple Effect Evaporator solutions to meet diverse industrial needs.

The Importance of Feed in Multiple Effect Evaporator Systems

The way feed in multiple-effect evaporator systems is managed plays a critical role in their efficiency and overall performance. The method of introducing and handling the feed in Multiple Effect Evaporators across the evaporator stages significantly impacts the system’s energy consumption, operational complexity, and suitability for different types of liquids.

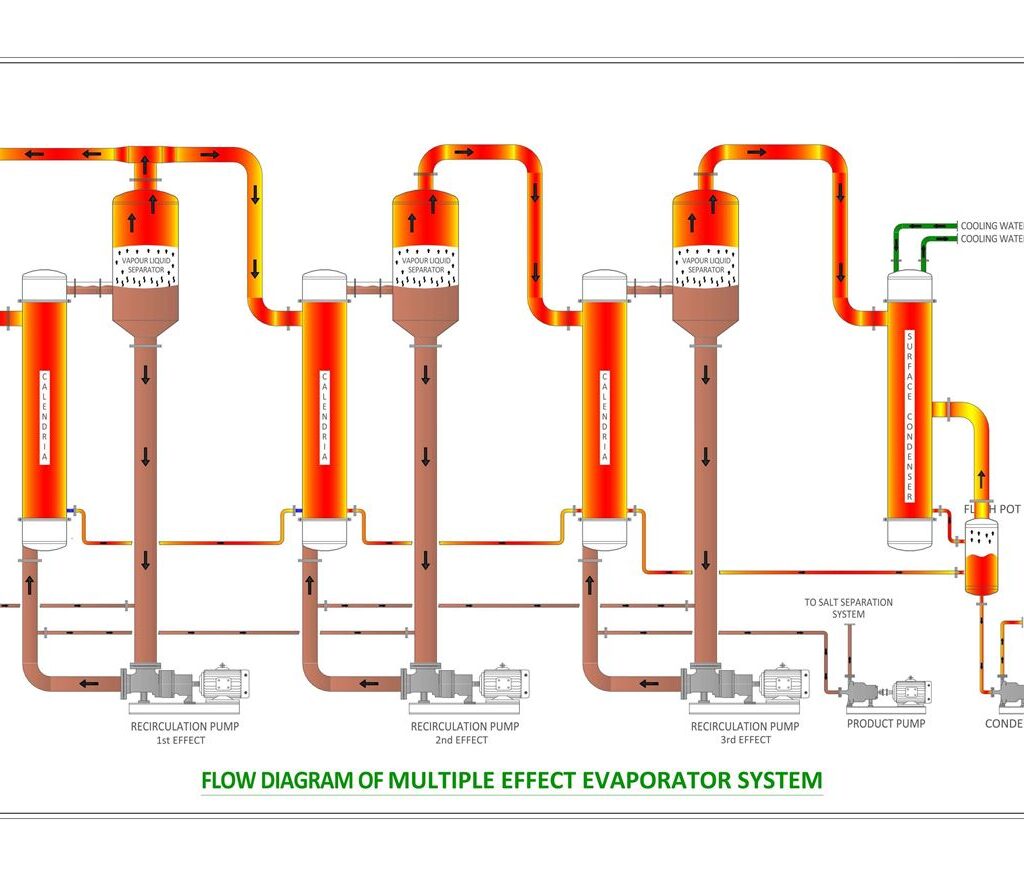

How Multiple Effect Evaporators Work

Single Effect vs. Multiple Effect Evaporators

In a single-effect evaporator, steam heats a liquid, causing the water in the liquid to evaporate. The resulting steam is then discarded, making the process energy-intensive. In contrast, a multiple-effect evaporator reuses the steam generated in one stage to heat the next stage, thus conserving energy and improving efficiency. Typically, MEEs consist of two or more stages, with triple-effect evaporators (three stages) being quite common.

Key Components of Multiple Effect Evaporators

- Heat Exchangers: Facilitate the transfer of heat from steam to the liquid feed.

- Condensers: Convert the used steam back into water.

- Pumps: Move the liquid feed through the various stages of the evaporator.

- Separator Vessels: Separate the evaporated steam from the concentrated liquid.

The Three Main Configurations Feed in Multiple Effect Evaporators

Goldfinch Evaporator Systems offers three main Feed in Multiple Effect Evaporators

- Forward Feed

- Backward Feed

- Parallel Feed

Each configuration has unique advantages making them suitable for different industrial processes.

Forward Feed In Multiple Effect Evaporator

How It Works

In a Forward Feed in Multiple Effect Evaporator, the liquid feed and steam are introduced into the first effect. The liquid is partially concentrated in the first stage and then flows to the next stage, and so on. Each subsequent stage operates at a lower pressure, allowing the steam from one stage to boil the liquid in the next.

Advantages

- Energy Efficiency: By reusing steam, forward feed systems achieve high energy efficiency.

- Simpler Design: Generally simpler to design and maintain.

- Lower Cost: Often have lower material and operating costs compared to more complex configurations.

Applications

Forward feed systems are suitable for processes where the liquid is not highly viscous and can handle temperature increases. Common applications include:

- Chemical Processing: Concentrating chemical solutions.

- Food and Beverage: Evaporating non-viscous liquids like fruit juices and milk.

Backward Feed In Multiple Effect Evaporator

How It Works

In a Backward Feed In Multiple Effect Evaporator, the dilute liquid feed is introduced into the last effect and pumped backward through the stages to the first effect. This arrangement typically requires pumps between each stage to move the increasingly concentrated liquid.

Advantages

- Handling Viscous Fluids: Better suited for viscous liquids because the liquid is more concentrated (and thus more viscous) at higher temperatures in the initial stages.

- Higher Capacity: Can achieve higher evaporation capacities, beneficial for large-scale operations.

Applications

Backward feed systems are ideal for processes involving viscous or heat-sensitive materials. They are commonly used in:

- Pharmaceuticals: Concentrating viscous solutions and extracts.

- Wastewater Treatment: Treating industrial effluents with high viscosity.

Parallel Feed In Multiple Effect Evaporator

How It Works

In a Parallel Feed In Multiple Effect Evaporator, the liquid feed is split and introduced into multiple stages simultaneously. Each stage operates independently, and the concentrated outputs from each stage are combined at the end of the process.

Advantages

- Flexibility: Offers flexibility in handling different feed compositions and flow rates.

- Uniform Temperature Control: Easier to maintain consistent temperatures across stages since each operates independently.

Applications

Parallel feed systems are suitable for processes requiring precise control over temperature and concentration, such as:

- Desalination: Handling varying feed salinity in desalination plants.

- Food Processing: Concentrating multiple streams of food products simultaneously.

Comparing Feed in Multiple Effect Evaporators Configurations

Energy Efficiency

- Forward Feed: High energy efficiency due to sequential steam use.

- Backward Feed: Also energy-efficient but requires more energy for pumping.

- Parallel Feed: Can be energy-efficient with proper control and synchronization.

Complexity and Cost

- Forward Feed: Simpler design with lower costs.

- Backward Feed: More complex with higher costs.

- Parallel Feed: Most complex and expensive, but offers high flexibility.

Suitability for Viscous Materials

- Forward Feed: Less suitable for highly viscous materials.

- Backward Feed: Best for viscous materials due to higher initial temperatures.

- Parallel Feed: Suitable for various viscosities with appropriate control.

Designing a Multiple Effect Evaporator

Goldfinch Evaporator Systems takes a meticulous approach to designing MEEs, considering several critical factors to ensure optimal performance:

Key Considerations

- Feed Characteristics: Understanding the feed’s properties, such as viscosity, temperature sensitivity, and concentration levels, is crucial.

- Heat Transfer Efficiency: Ensuring optimal heat transfer by selecting appropriate heat exchangers and maintaining high heat transfer coefficients.

- Liquid-Vapor Separation: Effective separation reduces product loss and improves quality.

- Energy Utilization: Maximizing energy efficiency through design and potential energy recovery techniques is essential.

Applications of Multiple Effect Evaporators

Industrial Wastewater Treatment

MEEs are highly effective for treating industrial wastewater, reducing parameters like Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), and Total Suspended Solids (TSS). They are used in:

- Chemical and Pharmaceutical Industries: Treating effluents with high organic loads.

- Textile and Dyeing: Concentrating and treating wastewater to minimize disposal costs.

Desalination

MEEs concentrate reject streams from reverse osmosis (RO) processes, recovering valuable water and reducing brine disposal volumes in desalination plants.

Food and Beverage Industry

MEEs concentrate products such as:

- Milk: Producing condensed milk and milk powder.

- Fruit Juices: Evaporating water to produce concentrated fruit juices.

Chemical Processing

In chemical processing, MEEs concentrate solutions and recover solvents, enhancing efficiency and sustainability.

Detailed Examination of Feed Configurations

Forward Feed Multiple Effect Evaporator

In a Forward Feed In Multiple Effect Evaporator, the process begins with the introduction of the feed and steam into the first effect. The steam heats the feed, causing it to partially evaporate. The partially concentrated liquid then flows into the second effect, where it is further concentrated, and this process continues through all the effects. The steam produced in the first effect is reused to heat the second effect, and so on, until the final effect, where the remaining liquid is highly concentrated.

Main Advantage

The primary advantage of the forward feed configuration is its simplicity. Because the steam and liquid flow in the same direction, the system can be designed with fewer pumps, reducing both the initial cost and the complexity of operation. Additionally, forward feed systems are more energy-efficient than single-effect systems because they reuse the steam multiple times.

Industrial Use

Forward Feed in multiple-effect evaporators is widely used in industries where the feed is not highly viscous and can tolerate higher temperatures. For example, in the chemical processing industry, forward feed systems are used to concentrate various chemical solutions. In the food and beverage industry, they are used to evaporate water from fruit juices, milk, and other non-viscous liquids.

Backward Feed Multiple Effect Evaporator

The backward feed configuration is designed to handle more viscous and heat-sensitive materials. In this configuration, the dilute liquid feed is introduced into the last effect and is pumped backward through the system to the first effect. This arrangement allows the more concentrated liquid, which is also more viscous, to be processed at higher temperatures in the initial stages.

Main Advantage

The primary advantage of the backward feed configuration is its ability to handle highly viscous materials. Processing more concentrated and viscous liquids at higher temperatures in the initial stages helps reduce viscosity and improve flow

in subsequent stages. This makes the backward feed configuration ideal for applications in industries where highly viscous materials are prevalent, such as pharmaceuticals and wastewater treatment.

Industrial Use

Despite these challenges, backward feed systems are indispensable in industries dealing with viscous or heat-sensitive materials. For instance, in pharmaceutical manufacturing, backward feed systems are employed to concentrate viscous solutions and extracts efficiently. Likewise, in wastewater treatment facilities, these systems play a crucial role in treating industrial effluents with high viscosity.

Parallel Feed Multiple Effect Evaporator

The parallel feed configuration is engineered to provide flexibility and precise control over the evaporation process. In this setup, the liquid feed is divided and introduced into multiple effects simultaneously. Each effect operates independently, and the concentrated outputs from each stage are combined at the process’s conclusion.

Main Advantage

One of the primary advantages of the parallel feed configuration is its flexibility. Since each effect operates autonomously, the system can adapt to handle varying feed compositions and flow rates effectively. This versatility makes parallel feed systems particularly well-suited for applications where feed characteristics fluctuate significantly, such as in desalination plants and food processing facilities.

Industrial Use

Parallel feed systems find widespread application in industries necessitating precise control over temperature and concentration. For instance, in desalination plants, parallel feed systems are employed to handle varying feed salinity levels effectively. Similarly, in the food processing sector, these systems are used to concentrate multiple streams of food products simultaneously, ensuring uniform quality and concentration levels.

Comparing Feed Configurations

Energy Efficiency

- Forward Feed: Achieves high energy efficiency by sequentially utilizing steam.

- Backward Feed: Also energy-efficient, but requires additional energy for pumping.

- Parallel Feed: Can be energy-efficient with proper control and synchronization.

Complexity and Cost

- Forward Feed: Characterized by simpler design and lower costs.

- Backward Feed: More complex and costly due to additional pumps and piping.

- Parallel Feed: Most complex and expensive, yet offers unparalleled flexibility.

Suitability for Viscous Materials

- Forward Feed: Less suitable for highly viscous materials due to incremental temperature increases.

- Backward Feed: Ideal for handling viscous materials, thanks to higher initial temperatures.

- Parallel Feed: Suitable for a wide range of viscosities with precise control.

Designing a Multiple Effect Evaporator

When designing an MEE, several factors must be carefully considered to ensure optimal performance and efficiency:

Key Considerations

- Feed Characteristics: Understanding the properties of the feed, including viscosity, temperature sensitivity, and concentration levels, is paramount.

- Heat Transfer Efficiency: Selecting appropriate heat exchangers and maintaining high heat transfer coefficients is critical for efficient operation.

- Liquid-Vapor Separation: Effective separation minimizes product loss and enhances product quality.

- Energy Utilization: Maximizing energy efficiency through design optimization and energy recovery techniques is essential for sustainable operation.

Applications of Multiple Effect Evaporators

Industrial Wastewater Treatment

Multiple Effect Evaporators are highly effective in treating industrial wastewater, reducing parameters such as Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), and Total Suspended Solids (TSS). They find application in:

- Chemical and Pharmaceutical Industries: Treating effluents with high organic loads.

- Textile and Dyeing: Concentrating and treating wastewater to reduce disposal costs.

Desalination

Multiple Effect Evaporators are employed to concentrate reject streams from reverse osmosis (RO) processes, recovering valuable water and reducing brine disposal volumes in desalination plants.

Food and Beverage Industry

Multiple Effect Evaporators are used to concentrate various products, including:

- Milk: Producing condensed milk and milk powder.

- Fruit Juices: Evaporating water to produce concentrated fruit juices.

Chemical Processing

In chemical processing, Multiple Effect Evaporators are utilized to concentrate solutions and recover solvents, enhancing efficiency and sustainability.

Conclusion

Multiple Effect Evaporators are versatile and efficient systems for evaporating water from various liquid feeds. The choice of feed configuration — Forward Feed, Backward Feed, or Parallel Feed—depends on specific process requirements, including feed characteristics, energy efficiency goals, and operational complexity.

Goldfinch Evaporator Systems specializes in designing and manufacturing high-quality Multiple Effect Evaporators tailored to meet diverse industrial needs. Our expertise ensures that clients achieve optimal performance, energy efficiency, and cost savings in their operations. Contact us today to learn more about how our solutions can benefit your operations and elevate your efficiency to new heights.

Also read Increasing the Efficiency by 10x with the Steam Economy of Multiple Effect Evaporator Systems

Feel free to follow us on LinkedIn