Evaporator Overview

- Evaporation is a process of concentrating solution by vaporizing a portion of the solvent. The solution comprises of solvent which is generally water and solute in the form of dissolved salts added due to different processes in the manufacturing unit. Evaporation is followed by crystallization or Filtration or drying based on type of salt in the solution.

- Filtration or Drying is the most common process that follows evaporation. Filtration is separation of precipitated solids from the Mother Liquor. It is carried out by suitable filter media (cloth, steel mesh, etc.) of suitable micron size. Drying is evaporating the remaining water from the concentrated Mother liquor to form dry solids.

- Crystallization is used for the formation of sizeable crystals generally by contact crystallization (seeding) and is followed by filtration.

- Evaporation system consists of Heat Exchangers (Calendria), Vapour Liquid Separators (VLS) and Condensers.The Heat Exchangers and Condensers are by and large Shell and tube type since they are the most economical.

- Evaporators can be designed as Single effect or Multiple Effect. In Single Effect Evaporators, steam is let into the shell side of the heat exchanger and the effluent to be evaporated is pumped through the tube side. The heated effluent is pumped to the Vapour Liquid Separator (VLS) where the vapours are separated from the liquid and concentrated effluent is again pumped back through the calendria by the recirculation pump. The vapour separated in VLS is condensed in the condenser and saturated effluent solution is removed from the system as concentrated product.

Why the Need for Evaporator

- Biological Process based wastewater Treatment plants are not able to treat high TDS wastewaters as microbes are not able to survive in such high TDS wastewater

- Biological Process are inefficient to treat high refractory or low BOD / COD ratio wastewaters

- Reverse Osmosis proves ineffective as High TDS and High COD effluent chokes the R.O Membranes

- Other options are practically and economically unfeasible

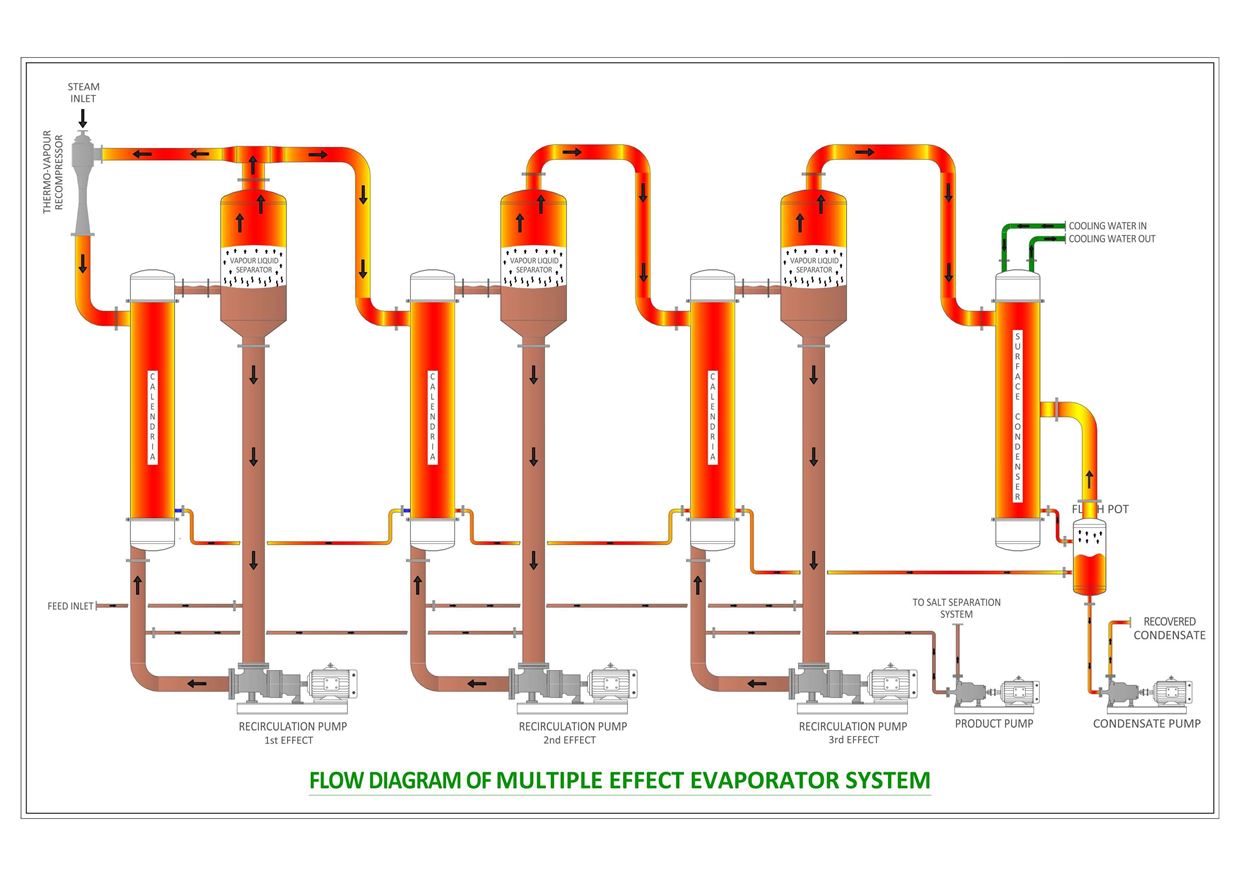

- In the Multiple Effect Evaporator System, the Steam/Hot oil is let into the shell side of the Heat Exchanger of the 1steffect (stage) while the vapour separated in the 1steffect is used as the heating medium for the 2ndeffect. Similarly, the vapour separated in 2ndeffect is used for heating in the 3rd effect, and so on. This method helps achieve the steam economy. The number of effects (stages) has to be optimized to achieve both steam economy and minimum capital cost.

- In addition the vapour recompressed from the succeeding effect can be used for heating the same effect. (Please see vapour recompression / TVR description below)

- Concentrated solute is passed onto the succeeding stages

- By theory to evaporate 1 kg of water we require 1 – 1.2 kg of steam.

- But in Multiple effect 1 kg of steam will evaporate more than 1 kg of water depending on the no. of effects.

- By theory we get steam economy = no. of effects i.e. in a three effect evaporator 1 kg of steam will evaporate approx. 3 kg of water.

Types of Evaporator System

Evaporators used in wastewater primarily fall in below categories

A)Depending on the type of Vapour compression

1)Thermo Vapour Recompression based Evaporators (TVR based Evaporator)

2)Mechanical Vapour Recompression based Evaporators (MVR based Evaporator)

B)Depending on Type of Liquid Flow

1) Forced Circulation Evaporators – Used in majority of the cases

2) Falling Film Evaporators – Used Rarely

What is Vapour Recompression

- Vapour Recompression is the use of the vapour generated from heating back to heat the same medium

- Vapour Recompression requires compressing the low-pressure vapour generated to increase the temperature of the vapour above that of the medium to be heated

- Vapour Recompression gives increased steam economy by more heat recovery

- Vapour Recompression is used in Multiple Effect Evaporators to achieve more heating in the earlier effects where the heat transfer coefficients are maximum thus reducing the net area of evaporation.

Vapour Recompression can be done using –

1) Thermal Energy using high pressure Boiler steam (Motive Steam) or

2) Mechanical energy of reciprocating / lobe compressors

A) Thermo Vapour Recompression (TVR) – When Thermal energy is used for vapour compression it is called Thermo Vapour Recompression (TVR) and the evaporator systems are called TVR based evaporators.

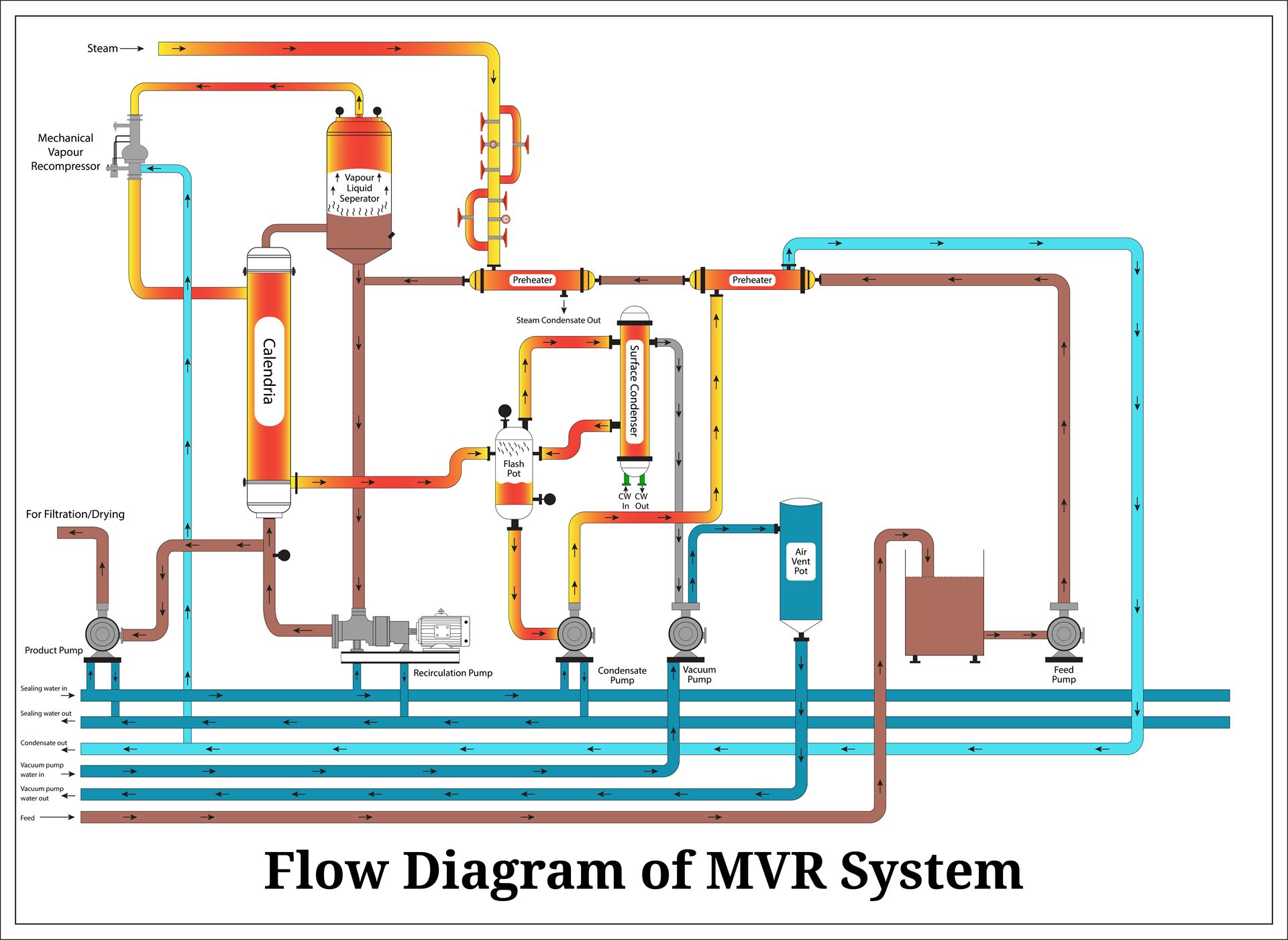

B) Mechanical Vapour Recompression (MVR) – When mechanical energy of reciprocating / lobe compressors is used for vapour compression it is called Mechanical Vapour Recompression (MVR) and the evaporator systems are called MVR based evaporators.

Thermo Vapor Recompression Based Evaporator

Please follow the process flow diagram and the description mentioned for Multiple Effect Evaporator System above.

Comparison Between TVR and MVR

TVR

- Uses Kinetic Energy of Steam

- No Moving Part

- Practically Zero or low maintenance

- Systems employing TVR have requirement of higher Footprint areas

- Steam dependent

- No Requirement of Power

- In TVR based systems Utilities are required

MVR

- Uses Mechanical Movement of Lobes

- Involvement of Moving Parts

- Requires Maintenance

- Systems employing MVR have requirement of lower footprint areas

- Power dependant

- High Requirement of power

- In MVR based systems No or very less utilities are required

Advantages of MVRE over TVR

- Steam Consumption in MVRE is between 10 – 20 % of TVR based evaporator

- It occupies 30 – 40 % of space required for Conventional MEE

- The requirement of cooling water as utility is very less thus saving the energy required for cooling tower

- The Opex (Power + Steam) for MVRE is 40 % less than the Opex (Power + steam) for conventional MEE

- Since the steam condensate does not mix with the evaporated process condensate it does not add to the hydraulic load for upstream polishing treatment and so the polishing treatment becomes cheaper

Comparison of Forced and Falling Film Evaporators

The Evaporator system can be Forced Circulation type or Falling Film type. In the Forced Circulation Evaporators the effluent is pumped through the calendria at a high velocity by the recirculation pump. In the Falling Film Type the liquid trickles from top to bottom forming a thin film along the inside wall of the tube. Generally for handling of effluents Forced Circulation Type evaporators are preferred as they are much more resistant to scaling and salting in the inside of the tubes than falling film type.

Forced Effect

- Uses High Velocity in the tube

- Very Efficient in handling liquids containing abrasive and corrosive solids as use of high velocity does not allow deposition of solids in tubes

- Distribution Mechanism not required

- Power Consumption higher

Falling Film

- Uses Low velocity in the tube

- Inefficient in handling liquids containing abrasive and corrosive solids as use of low velocity allow deposition of solids in tubes

- Proper Distribution system must for achieving desired heat transfer

- Power Consumption lower

Type of Heating Medium

Below are frequently and easily available heating mediums

- Dry and Saturated Steam

- Hot Oil

- Hot water

Comparison for Steam and Thermic Fluid

Steam, Hot water and Thermic Fluid can be used as the heating medium for evaporators. Steam is preferably used as a heat source for evaporation because it is clean fluid and comparatively the most economical.

Steam

- Heat Transfer is by condensation of steam. So the effective areas are lower

- Clean handling

- The effective operating cost is less

- Vapour compression is possible for achieving economy

- Higher pressure is required for achieving the desired temperature

Thermic Fluid

- Heat transfer is by sensible heat. So the effective areas are higher

- Fouling is much higher in condensers

- The effective operating cost is more

- Vapour compression not possible

- Lower pressure is required for achieving the desired temperature

Zero Liquid Discharge

Goldfinch has designed and executed many Zero Liquid discharge (ZLD) projects for various kinds of challenging effluents.

The recycled wastewater is being regularly used as cooling tower make up, vessel washings and sometimes as process water also. We have also installation where the recycled wastewater is used as Boiler feed.

The typical ZLD schemes comprise of Bio – ETP followed by RO. RO reject is evaporated in evaporator. But as in case of high TDS effluents, the ZLD schemes comprise of Multiple Effect Evaporator upfirst. The condensate of MEE is then treated in Bio – ETP followed by RO. The RO reject is then recycled back to MEE in closed loop.

Goldfinch has successfully designed and executed ZLD projects for speciality chemicals, API, paint effluents etc.

FAQs | Evaporator Overview

Goldfinch Evaporators specializes in designing, manufacturing, and providing services for Multiple Effect Evaporators (MEE), Mechanical Vapor Recompression Evaporators (MVRE), and Zero Liquid Discharge (ZLD) systems. Our primary goal is to offer efficient and sustainable evaporation solutions for industrial wastewater management across various sectors in India.

Multiple Effect Evaporators (MEE) use the principle of vaporizing water to separate it from contaminants. This system involves multiple stages where steam from one effect is used to heat the next, improving energy efficiency. MEEs are ideal for industries looking to reduce energy consumption and operational costs while achieving effective wastewater treatment.

Mechanical Vapor Recompression Evaporators (MVRE) recycle the vapor produced during evaporation by compressing it to a higher pressure and temperature. This compressed vapor is then used as a heating medium, significantly reducing energy requirements. MVRE systems are highly efficient and suitable for applications requiring energy conservation and low operational costs.

Zero Liquid Discharge (ZLD) is a wastewater management approach that ensures all water is recovered and reused, leaving zero discharge at the end of the process. ZLD systems integrate advanced evaporation and crystallization technologies to recover water and valuable by-products, making them crucial for industries facing stringent environmental regulations.

Goldfinch Evaporators serve a wide range of industries, including pharmaceuticals, chemicals, textiles, food and beverage, and power generation. Our systems are designed to handle diverse wastewater challenges, ensuring compliance with environmental standards and promoting sustainable industrial practices.

Goldfinch Evaporators offers comprehensive services, including system design, manufacturing, installation, commissioning, and maintenance. Our expert team provides tailored solutions to meet specific industry requirements, ensuring optimal performance and longevity of the evaporation systems.

Goldfinch Evaporators Overview adheres to stringent quality control measures throughout the manufacturing process. We use high-quality materials, advanced technologies, and rigorous testing to ensure our products meet international standards. Our commitment to quality ensures reliable and efficient performance of our evaporation systems.

Goldfinch Evaporators stands out for its expertise, innovation, and customer-centric approach. We offer customized solutions, energy-efficient technologies, and robust after-sales support. Our dedication to sustainability and compliance with environmental norms makes us the preferred choice for industrial evaporation needs in India.

Goldfinch’s ZLD systems significantly reduce the environmental footprint of industrial processes by ensuring no liquid waste is discharged. These systems recover and reuse water, minimize waste generation, and promote resource conservation, contributing to sustainable industrial practices and regulatory compliance.

To discuss your evaporation needs and get a tailored solution, you can contact Goldfinch Evaporators through our website’s contact form, email us at info@goldfinchevaporators.com, or call our customer service helpline. Our team is ready to assist you with expert advice and comprehensive support.