Leading MEE Manufacturer

Goldfinch Evaporation Systems specializes solely in designing and implementing Evaporator & ZLD Projects tailored to the needs of the wastewater and process industry, including multiple effect evaporators, Mechanical Vapour Recompressor Evaporator(MVRE), Agitated Thin Film Dryers and Stripper Systems.

Utilizing cutting-edge software for thermal design, our Design team customizes Evaporation systems to optimize both initial investment and ongoing operational costs.

Get a Quote within 1 working day!

Who We Are

Goldfinch Evaporation Systems has executed numerous projects across India and internationally, such as Multiple-Effect Evaporators (MEE), Mechanical Vapour Recompression Evaporators (MVRE), and Salt Recovery Systems.

Many of our projects involve complex wastewater compositions containing various salts and organic compounds, as well as process effluents and RO reject streams.

We operate our manufacturing facility spanning 10,000 square feet for the fabrication of Heat exchangers and pressure Vessels ensuring quality control and timely delivery.

Multi Effect Evaporators for each Industry

Multiple Effect Evaporator Manufacturer (MEE)

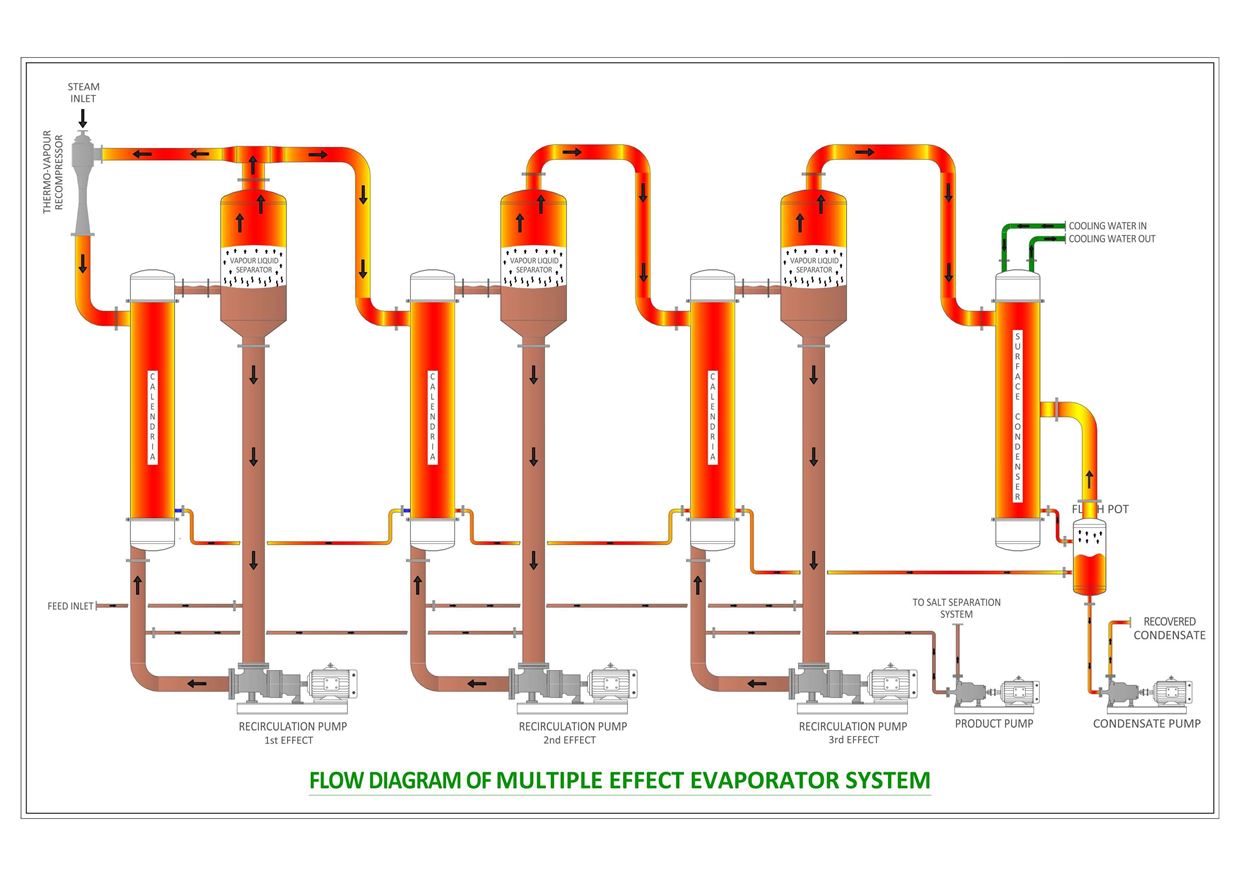

- In the Multiple Effect Evaporator Manufacturer System, Steam or Hot oil is introduced into the shell side of the Heat Exchanger in the first stage. The vapor generated in this stage serves as the heating medium for the second stage, while the vapor separated in the second stage is utilized for heating in the third stage, and so forth. This sequential utilization enhances the steam economy. Optimizing the number of effects (stages) is crucial for achieving an optimal balance between steam economy and minimizing capital expenditure.

- In addition the vapour recompressed from the succeeding effect can be used for heating the same effect.

- Concentrated solute is passed onto the succeeding stages

- By theory to evaporate 1 kg of water we require 1 – 1.2 kg of steam.

- But in Multiple effect 1 kg of steam will evaporate more than 1 kg of water depending on the no. of effects.

- By theory we get steam economy = no. of effects i.e. in a three effect evaporator 1 kg of steam will evaporate approx. 3 kg of water.

Types of Evaporation System

Evaporators used in wastewater primarily fall in below categories

A)Depending on the type of Vapour compression

1)Thermo Vapour Recompression based Evaporators (TVR based Evaporator)

2)Mechanical Vapour Recompression based Evaporators (MVR based Evaporator)

B)Depending on Type of Liquid Flow

1) Forced Circulation Evaporators – Used in majority of the cases

2) Falling Film Evaporators – Used Rarely

Why Choose Goldfinch Evaporator Systems?

Unmatched Expertise: With years of experience and a team of seasoned professionals, we possess unparalleled expertise in designing, manufacturing, and installing MEE Manufacturer systems tailored to your specific requirements.

Cutting-edge Technology: Our commitment to innovation drives us to incorporate the latest advancements in evaporation technology, ensuring optimal efficiency, reliability, and sustainability in all our systems.

Customized Solutions: We understand that each industry has its unique challenges and demands. That’s why we offer bespoke solutions designed to address your individual needs, whether it’s wastewater treatment, product concentration, or resource recovery.

Quality Assurance: Quality is at the forefront of everything we do. From the selection of premium-grade materials to rigorous testing protocols, we uphold the highest standards to deliver superior products that stand the test of time.

Choose Goldfinch Evaporators for MEE Manufacturers

Our Range of MEE Systems

For Industrial Applications: From food and beverage to pharmaceuticals and chemicals, our industrial-grade MEE Manufacturer systems are engineered to deliver exceptional performance, efficiency, and cost-effectiveness.

Wastewater Treatment: Combat environmental challenges with our advanced MEE Manufacturer solutions designed to efficiently treat and minimize wastewater, ensuring compliance with regulatory standards while maximizing resource recovery.

Product Concentration: Enhance the quality and value of your products with our precision-engineered MEE systems that facilitate efficient concentration processes, allowing you to achieve desired levels of purity and consistency.

Our Projects

Goldfinch Advantage

Partner with Goldfinch Evaporator Systems and experience the unparalleled quality, reliability, and efficiency of our MEE Manufacturer solutions. Whether you’re looking to optimize your industrial processes, achieve sustainable wastewater management, or enhance product quality, we have the expertise and technology to exceed your expectations.

FAQs | Multiple Effect Evaporator

A Multi Effect Evaporator (MEE) is a thermal evaporation system that utilizes multiple stages of evaporation to efficiently concentrate a liquid solution, such as wastewater or product streams. By utilizing the latent heat from the vapor generated in each stage, MEE systems achieve high levels of energy efficiency, making them ideal for various industrial applications.

In a Multi Effect Evaporator Manufacturer , heat is applied to the liquid solution in multiple stages, typically arranged in series. As the solution passes through each stage, it undergoes partial evaporation, with the vapor generated in one stage serving as the heating source for the next stage. This cascading effect significantly reduces energy consumption compared to single-effect evaporation systems.

MEE Manufacturer systems find applications across a wide range of industries, including but not limited to:

- Food and beverage processing

- Pharmaceutical manufacturing

- Chemical processing

- Wastewater treatment and recycling

- Desalination and water purification

The key advantages of Multi Effect Evaporator Manufacturer systems include:

- High energy efficiency due to the utilization of latent heat

- Reduced operating costs and lower energy consumption

- Compact footprint and modular design for easy integration

- Customizable configurations to meet specific process requirements

- Environmentally friendly solution for wastewater treatment and resource recovery

At Golfinch Evaporator Systems, we understand that every industry and application has unique requirements. Our team of experts works closely with clients to design and engineer bespoke MEE Manufacturer solutions tailored to their specific needs. Whether you require a standard system or a customized configuration, we have the expertise and flexibility to deliver optimal results.

We provide comprehensive after-sales support and services to ensure the continued performance and reliability of our MEE systems. Our services include installation, commissioning, operator training, preventive maintenance, and technical assistance. Additionally, we offer spare parts supply and system upgrades to enhance the longevity and efficiency of your equipment.

To request a quote or inquire about our MEE Manufacturer solutions, simply contact us through our website or reach out to our sales team directly. We will promptly assess your requirements and provide you with a tailored proposal outlining the specifications, pricing, and delivery timeline for your desired MEE system.