Leading in MVR Evaporator Solutions in India

- As a notable establishment in the Indian market, it focuses on innovative water recovery and liquid separation equipment, Goldfinch Evaporators Pvt. Ltd. manufactures Leading advanced Mechanical Vapour Recompression (MVR) evaporators. Goldfinch Evaporators In MVR Evaporation Systems and Multi-Effect Evaporators are unsurpassed as they are an ISO 9001:2015 certified company. These modern trends are directed toward particular industries that advocate for the safe use of energy-efficient evaporation technology. Below is a brief description of the MVR evaporators and the reasons why Goldfinch Evaporators Pvt. Ltd. Is one of the top suppliers, exporters, and manufacturers of the MVR in India.

Get a Quote within 1 working day!

Who We Are

Goldfinch Evaporation Systems has executed numerous projects such as Multiple Effect Evaporator (MEE), Mechanical Vapour Recompressor Evaporators (MVRE), and Salt recovery systems across India and internationally.

Many of our projects involve complex wastewater compositions containing various salts and organic compounds, as well as process effluents and RO reject streams.

We operate our own manufacturing facility spanning 10,000 square feet for the fabrication of Heat exchangers, Pressure Vessels ensuring quality control and timely delivery.

Definitional Analysis of MVR- Mechanical Vapour Recompression

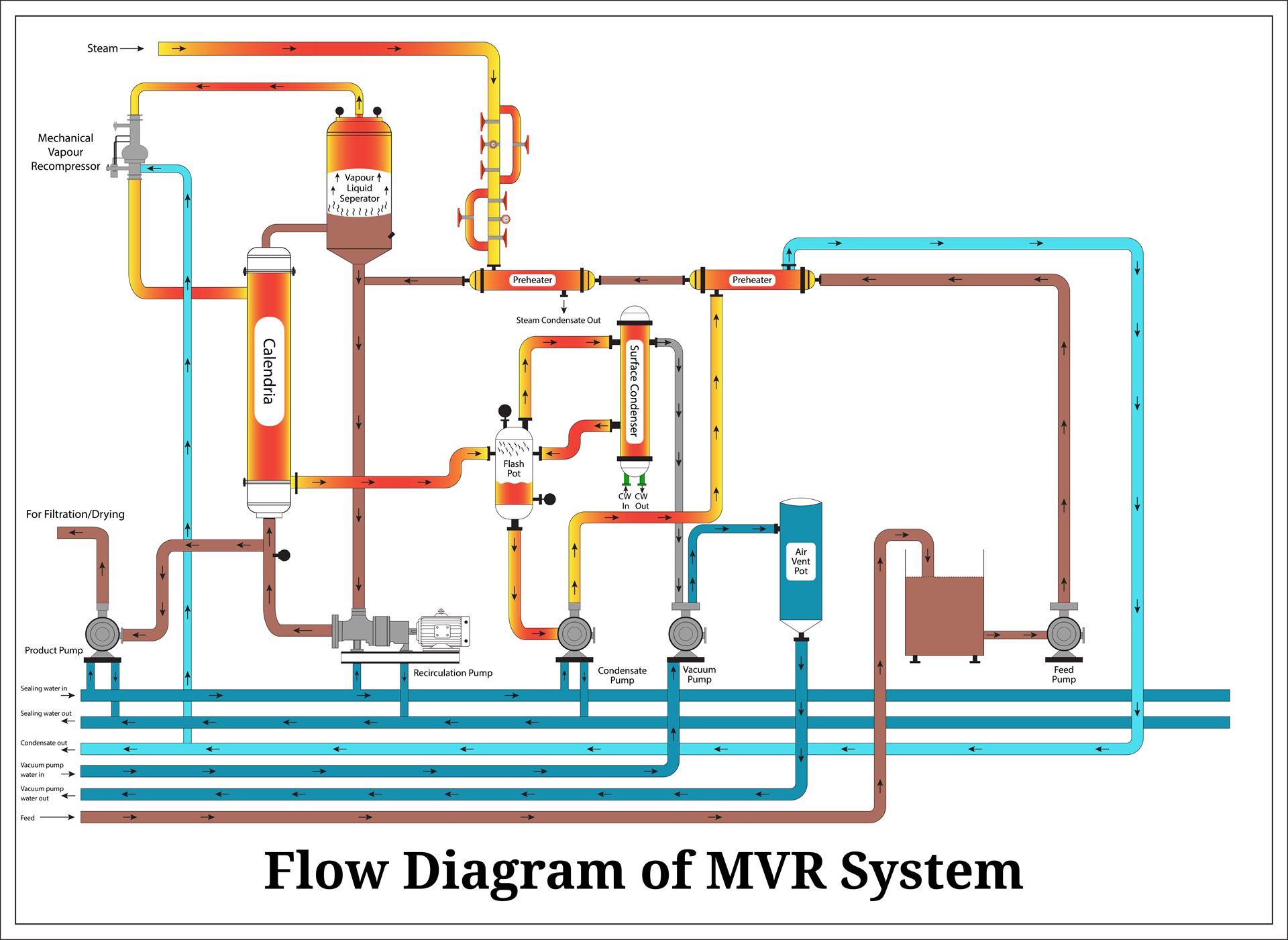

How a MVR Evaporator Operates

Mechanical vapour compression (MVR) evaporation is far more energy efficient in taking out water from a mixture than other techniques and also helps reduce waste. This technique involves compressing, heating, and then using the vapour produced during evaporation as a heat source. MVR evaporators recycle a lot of energy and thus, significantly reduce the cost of the process and its environmental effect, making them an ideal technology for eco-friendly industrial processes.

- An MVR evaporator is designed to compress the vapour generated during the evaporation process. Below is how it works

- The evaporation step the liquid component is fed into an evaporator, which partially transforms the liquid into vapour.

- Compression stage the material is subjected to mechanical compression by a compressor to increase the temperature and pressure of the vapour.

- Heat transfer stage more evaporation takes place due to the heat released into the liquid solution by the compressed vapour which acts as the heating medium.

- Condensation stage after the process is complete, the vapours that have lost their heat may either be returned to the system or simply discarded as per the requirement of the process.

How the MVR Evaporator Plant Functions

For greater efficiency, there are several steps involved in operating the MVR evaporator plant

- Introduction of the Feed Solution this is the liquid solution that will undergo evaporation.

- Vapor generation & compression the mechanically generated vapour is then compressed to raise its temperature and pressure.

- Heat exchange & evaporation the thermal energy from this compressed vapour results in more liquid evaporation.

- Condensation collection where removed condensed vapour is either discharged or returned to the process.

- Continuous cycle the process is repeated hence energy conservation and continuous operation are achieved.

Contact Us for your MVR Evaporator

A Brief Overview of the Mechanical Vapour Recompression Evaporators from Goldfinch Evaporators

Energy Utility: The tendency or practice of saving energy through its recycling by way of the use of vapour.

Environment-Friendly Operations: Helps in minimizing unnecessary emissions hence ideal for clients seeking green alternatives.

Small Size: A versatile design suitable for different types of industrial settings without occupying too much space.

Complex Controls: Ensures the steaming even in the best condensation evaporation is carried through efficiently for the process.

Strong Components: Built from high-quality raw materials to ensure low repair costs and durable lifespan.

Product Specifications

Model: Customizable models available

Capacity: Tailored to client requirements

Material: High-grade stainless steel and other robust materials

Energy Source: Electricity-driven compressor

Applications: Food and beverage processing, wastewater treatment, chemical recovery, and more.

Advantages of MVR Plants

Less Operating Costs: The reuse of vapour reduces energy costs thereby reducing the overall costs incurred.

High Water Recovery Rate: Water recovery can be as much as 95%, which is important for companies that focus on resource utilization.

Less Impact on the Environment: Helps conserve energy and by doing so reduces emissions of gasses that contribute to global warming.

Modular design: Suitable for industries with diverse processing capacities and specific water quality requirements.

Goldfinch – A Leader in MVR Evaporator Technology

Why Choose Goldfinch MVR Evaporator Technology?

Goldfinch Evaporators Pvt. Ltd. is one of the MVR evaporator manufacturing companies in India. It has maintained its reputation for providing quality products to clients and adhering to the set ISO standards. Due to our expertise in Multi-Effect Evaporators and MVR Evaporation Systems and their applications, we have become the partner of choice for green evaporation solutions. The goals we set forth are:

Creativity: A process in which the existing designs undergo constant modification for more efficiency.

Quality Control: Meeting the stringent standards of ISO 9001:2015.

Industry Specification: Designing specific solutions for specific categories of industries.

Benefits of MVR Evaporator

Energy Saving: Uses up to 90% less power than conventional evaporators.

Less Maintenance: Designed to operate with minimal maintenance and downtime.

Versatility: Designed for various sectors with effective liquid processing requirements.

Applicable Industries for MVR Evaporators

Processing of food and drinks: Effective in reducing the water content in dairy products, juices, and other such items.

Pharmaceuticals: Helps in the efficient reduction of the volume of active substances.

Waste treatment: Minimizes the amount of water in the treated waste streams of various industries.

Chemical Industry: Helps in maximizing recycling by evaporating and concentrating liquors during the manufacture of chemicals.

Why Choose Goldfinch MVR evaporator technology?

Goldfinch Evaporators Pvt. Ltd. boasts of being at the forefront of Mechanical Vapor Recompression Evaporation solutions with reliable, efficient, and eco-friendly systems across the globe. Using advanced MVR evaporator technology, We help companies optimize their operations without compromising sustainability and modernity. Our options are engineered to meet the specific needs of each industry to ensure better performance and minimal environmental impact.

Our Projects

FAQs

Mechanical Vapor Recompression Evaporator

MVRE systems recycle vapor as a heat source for the evaporative process by raising its temperature and pressure using a mechanical compressor. This self-sustaining cycle is an energy-efficient option since it lessens the requirement for outside energy input. The MVRE systems from Goldfinch Evaporators are designed for optimal efficiency, assisting businesses in achieving cost-effective and environmentally friendly evaporation processes.

Industries with high evaporation requirements, including pulp and paper, chemicals, food processing, pharmaceuticals, and wastewater treatment, benefit from MVRE technology. These industries make extensive use of Goldfinch Evaporators’ MVRE systems, which provide dependable and effective waste reduction and resource recovery solutions.

The MVRE systems from Goldfinch Evaporators have several benefits:

Energy Efficiency: Reduces energy expenses by recycling energy within the system.

Cost Savings: Lowers operating expenses by using less energy.

Environmental Impact: Promotes sustainable activities by cutting waste and energy use.

High Reliability: Our MVRE systems are designed to withstand harsh industrial environments and deliver reliable performance over time.

Leading evaporative technology company Goldfinch Evaporators has a wealth of expertise creating MVRE systems that meet customer requirements. We are dedicated to offering state-of-the-art, dependable, and energy-efficient solutions, supported by a group of professionals who provide all-encompassing assistance from installation to upkeep.

You can visit our website or contact Goldfinch Evaporators at [Contact Information] with any questions you may have regarding MVRE systems or any other evaporative solutions. Our staff is available to help you with personalized solutions and respond to any inquiries you might have.

MVRE systems use a lot less energy than conventional evaporators. They greatly reduce energy requirements by recycling heat through mechanical recompression. The MVRE systems from Goldfinch Evaporators are perfect for businesses trying to minimize evaporation expenses and maximize energy use.

To guarantee optimal performance and lifetime, MVRE systems need routine maintenance, which includes examinations of the compressor, pumps, and heat exchangers. In order to help customers optimize system efficiency and save downtime, Goldfinch Evaporators offers extensive maintenance support.

Indeed, Goldfinch Evaporators creates MVRE systems that are adaptable and compatible with current industrial procedures. Our staff works closely with clients to guarantee a smooth integration that is customized to meet the unique requirements and operational objectives of each site.

In ZLD systems, when total water recovery and waste reduction are necessary, MVRE technology works incredibly well. By lowering wastewater volumes and reusing water in industrial processes, Goldfinch Evaporators’ MVRE systems facilitate effective water evaporation and help ZLD goals.